Blog

Dental Die and Casting vs. Dentistry CAD/CAM: Choosing the Right Approach for Your Dental Lab

While CAD/CAM technology offers numerous benefits such as increased efficiency and precision, it is not always the best option for every patient. Factors such as the patient’s dental condition, age, and overall health can affect their suitability for CAD/CAM dentistry. They still need casting restoration in the dental lab. Casting restorations still play a significant role in dental laboratories for several reasons:

1. Castings provide a more precise fit than CAD/CAM restorations.

2. Castings can be customized more easily to match the patient’s anatomy.

3. Castings can be designed to provide better strength and durability than CAD/CAM restorations.

4. Castings are more cost-effective than CAD/CAM restorations.

5. Castings can be designed to provide a more aesthetic appearance than CAD/CAM restorations.

6. Castings are more time-efficient than CAD/CAM restorations.

7. Castings provide a greater range of customization options for complex cases.

8. Castings are more biocompatible than CAD/CAM restorations.

It is essential for dental labs to offer both options to ensure that patients receive the best possible care. By providing both CAD/CAM dentistry and casting restoration, dental labs can accommodate the needs and preferences of a diverse range of patients. Dental labs can also use both technologies in combination for optimal results. For example, CAD/CAM technology can be used to create a digital model of the patient’s teeth, which can then be used to create a physical model through casting restoration.

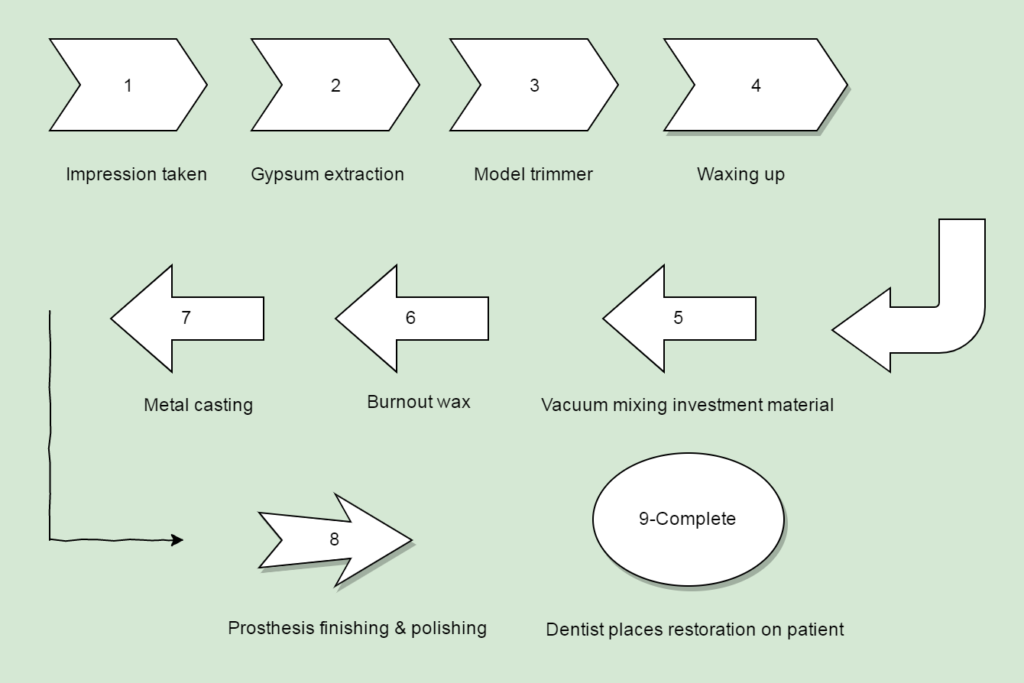

Most common die and casting fabrication in laboratories procedure

The dental die and casting fabrication procedure requires skilled technicians and the use of specialized equipment to achieve precise and functional dental restorations. Each step is crucial in ensuring the final restoration meets the patient’s needs and provides optimal oral health and aesthetics.

The dental die and casting fabrication procedure involves several steps to create accurate and functional dental restorations. Here is an overview of the process:

1. Impression materials

2. Dental stone or gypsum

3. Dental die trimmer

4. Dental wax

5. Dental investment material

6. Dental burnout furnace

7. Dental casting machine

8. Dental instruments (such as burs and handpieces)

9. Dental adhesive or cement(In dental clinic office)

Die and casting equipment function in laboratories

- Dental Casting Machine: This machine is used to cast dental restorations such as crowns, bridges, and partial dentures. It melts and casts metal alloys into the desired shape.

- Dental Burnout Furnace: A burnout furnace is used to eliminate wax patterns from investment molds before casting. It applies heat to remove the wax, leaving behind a cavity that will be filled with molten metal.

- Dental Vibrator: A dental vibrator is used to remove air bubbles from poured dental stone or investment materials when making dental models or molds. It helps ensure accurate reproduction of details.

- Dental Vacuum Mixer: This equipment is used to mix dental investment materials, such as gypsum or dental stone, with water. It ensures a consistent and homogeneous mixture without air bubbles.

- Dental Vibrating Table: A vibrating table is used to settle poured dental stone or investment materials into molds. It helps improve the flow and distribution of the material, resulting in better quality casts.

- Dental Lab Press: A dental lab press is used to compress and shape dental ceramics or composite materials. It applies pressure and heat to produce dental restorations like veneers, inlays, or onlays.

- Dental Die Trimmer: This machine trims excess plaster or stone from dental models or dies. It provides precise and smooth surfaces for accurate fabrication of dental restorations.

- Dental Surveyor: A dental surveyor is a versatile instrument used for analyzing and planning dental restorations. It helps in measuring and marking the orientation, contours, and axial inclination of teeth.

- Dental Milling Machine: A dental milling machine is used to fabricate dental restorations from solid blocks of materials, such as ceramics or metal alloys. It uses computer-aided design/computer-aided manufacturing (CAD/CAM) technology for precision milling.

- Dental Polishing Equipment: This includes various handpieces, burs, discs, and polishing compounds used to finish and polish dental restorations. It helps achieve a smooth and aesthetic surface.

- Dental Sandblaster: A dental sandblaster is used to clean dental restorations by propelling abrasive particles onto their surfaces. It removes surface contaminants and enhances bonding.

- Dental Articulator: An articulator is used to simulate jaw movements and hold dental models in a fixed relationship. It aids in the fabrication of dental restorations that accurately replicate the patient’s occlusion.

These are some of the essential die and casting equipment used in a dental lab. However, it’s important to note that different dental labs may have variations in the specific equipment they use based on their workflow and specialization.

Dental Lab Shop Provides Traditional Casting And CAD/CAM Innovation Equipment & Materials

Upgrade your dental laboratory or set up a new state-of-the-art facility with Dental Lab Shop. We offer a comprehensive range of die and casting equipment, as well as cutting-edge CAD/CAM technology and materials, all available for worldwide shipping. Our extensive inventory is stocked and ready to go, ensuring prompt delivery to your doorstep.

Whether you’re looking to enhance your casting capabilities or embrace the efficiency of CAD/CAM dentistry, Dental Lab Shop is your one-stop destination. From dental casting machines, burnout furnaces, and vibrating tables to advanced CAD/CAM dentistry milling machines, and high-quality materials, we have everything you need under one roof.

We partner with leading manufacturers in the industry, ensuring that you receive cutting-edge technology that meets the highest standards. With our worldwide shipping capabilities, distance is not a barrier to upgrading your dental laboratory. No matter where you are located, we’ll swiftly process your order and get it on its way to you. Our efficient shipping processes ensure that your equipment arrives in a timely manner, so you can quickly get started on your dental restorations.

At Dental Lab Shop, we understand the importance of staying ahead in the ever-evolving field of dentistry. That’s why we provide a comprehensive range of die and casting equipment alongside CAD/CAM solutions, catering to all your laboratory needs. Trust us as your reliable partner in elevating your dental laboratory to new heights of precision, efficiency, and success.