The advent of fast sintering zirconia is set to revolutionize the field of dental restoration. Traditional zirconia sintering is a time-intensive process, taking upwards of 10 hours to fully densify zirconia blocks through heat treatment. However, new fast sintering zirconia formulations enable the creation of fully sintered zirconia restorations in as little as 2 hours. This represents an 80% reduction in production time, allowing dental laboratories to increase patient flow and decrease turnaround times.

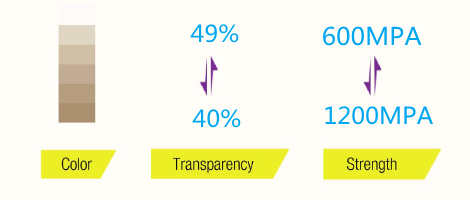

Critically, the mechanical properties and aesthetics of fast sintering zirconia match or exceed those of conventional zirconia. For example, a recently developed fast sintering zirconia features built-in shade gradients with six distinct layers of color transition. This mimics the subtle color variation seen in natural teeth for highly aesthetic restorations. The zirconia formulation also has a controlled transparency gradient, transitioning from 49-40% translucency from the gingival to incisal areas. This further augments aesthetic results, enabling lifelike light transmission and internal color blending.

Additionally, the fast sintering zirconia displays advanced biomechanics akin to natural dentition. At the critical gingival area, flexural strength exceeds 1200 MPa for fracture resistance under masticatory loads. This then naturally transitions incisally towards 600 MPa to mimic the decreased bulk and durability of incisal edges. This biomechanics gradient imparts advanced structural integrity while still following stress distribution pathways seen in natural tooth morphology.

Finally, the fact that fast sintering zirconia blocks can be rapidly processed in only 2 hours has profound workflow implications. By enabling same-day turnaround, dental laboratories can maximize productivity through just-in-time production cycles. This also minimizes the need for large zirconia block inventories. Moreover, by outsourcing overflow work during high demand periods, production bottlenecks can be avoided. Operating costs also benefit over the long term, with reduced labor, equipment, and inventory carrying costs.

Fast-sintering capbility material in dentistry CAD/CAM:

The Rapid Sintering Gradient Zirconia Blocks are designed for efficient and fast sintering, completing the procedure in just 2 hours. The material features a three-dimensional gradient with progressive transitions in color, transparency, and strength to closely mimic natural tooth morphology.

Gradient Transitions:

- Color Transition: The zirconia block exhibits a 6-layer color transition, providing a perspective shade gradient across its surface.

- Transparency Transition: The transparency of the material transitions naturally from 49% to 40%, mimicking the natural progression from gingiva to incisal.

Strength Characteristics:

- The flexural strength of the zirconia block follows a natural progression, with gingival strength exceeding 1200 MPa and transitioning gradually to incisal strength at 600 MPa.

Flexural strength specifications:

| LAYER | PERCENTAGE | FLEXURAL STRENGTH (MPA) |

|---|---|---|

| 1 | 20% | 600 |

| 2 | 15% | 720 |

| 3 | 15% | 840 |

| 4 | 15% | 960 |

| 5 | 15% | 1080 |

| 6 | 20% | 1200 |

Application: The combination of rapid sintering capability, shade/transparency gradients, and the natural strength progression makes this zirconia block ideal for creating strong and aesthetically natural dental restorations.

In summary, the introduction of fast sintering technology to zirconia-based restorations represents a paradigm shift. The combination of shortened production times and enhanced mechanical-optical properties unlocks new potential in terms of productivity, profitability, and patient satisfaction. Same-day crowns and bridges are now a realistic option even for high volume labs. As material formulations and furnace technologies continue advancing, fast sintering promises to become the new industry standard in the coming years.