Blog

The titanium crowns in dentistry cad-cam application

Titanium alloy Grade 5 standard in dentistry application

Titanium alloy is an increasingly popular material used in the dental industry. It is a strong and durable metal alloy that provides a number of advantages in dental restorations and prosthetics. Grade 5 titanium dental alloy is used to create custom dental appliances, implants, and crowns that provide a comfortable and aesthetically pleasing fit.

Grade 5 titanium alloy is a metal alloy composed of titanium, niobium, and aluminum. It is a strong and durable material that is highly biocompatible and non-toxic, making it a safe choice for dental restorations. The alloy is also lightweight, making it easier to work with and less stressful on the patient’s jaw.

The most common application of titanium dental alloy is in the creation of custom dental implants. The alloy is used to create a post that is surgically implanted into the jawbone. Once the post is in place, a custom crown is then fitted over the post. The crown is a precise replica of the patient’s missing tooth and is designed to fit the patient’s mouth perfectly.

Titanium alloy is also used to create custom dental crowns. The alloy is heated and shaped to match the patient’s natural tooth shape. This allows for a precise and aesthetically pleasing fit that is resistant to wear and tear. The alloy is also resistant to staining and discoloration, helping to maintain a natural appearance over time.

Titanium alloy is also used to create dentures and bridges. The alloy is heated and shaped to create the desired prosthetic and is then fitted to the patient’s mouth. The alloy is highly durable, allowing for a long-term solution to missing teeth.

Titanium alloy is an increasingly popular material used in dental restorations and prosthetics. It is a strong and durable metal alloy that is highly biocompatible and non-toxic, making it a safe choice for dental applications. The alloy is also lightweight and resistant to wear and tear, providing a long-term solution for missing teeth.

Dental Titanium Blocks and the Application of CAD/CAM Milling in Dentistry

The use of dental titanium blocks and CAD/CAM milling technology is an increasingly popular method of creating custom dental prosthetics. This technology is used to create unique dental appliances that are specifically designed to meet the patient’s needs and provide a comfortable and aesthetically pleasing fit.

Dental titanium blocks are used in the production of custom dental prosthetics. These blocks are made of pure titanium, which is non-toxic and highly biocompatible. The blocks are designed to be compatible with various CAD/CAM milling machines, allowing for precise and accurate customizations. The blocks come in a variety of sizes, shapes to match the patient’s specific needs.

CAD/CAM milling technology is used to create custom dental prosthetics out of the titanium blocks. The blocks are loaded into the CAD/CAM milling machine and the desired prosthetic is digitally designed. The machine then mills the blocks into the desired shape and size according to the design specifications. The prosthetic (crown) is then ready to be fitted to the patient’s mouth.

This method of creating custom dental prosthetics offers a number of advantages over traditional methods. The prosthetics are made to fit the patient’s mouth exactly, providing a comfortable and aesthetically pleasing fit. The prosthetics are also highly durable and resistant to wear and tear, which helps to ensure their longevity. Additionally, the CAD/CAM milling technology is highly accurate, providing precise and detailed customizations to the prosthetic, it includes the crown, bridge, implant abutment etc.

The application of CAD/CAM milling technology and dental titanium blocks is an increasingly popular method of creating custom dental prosthetics. This technology allows for precise and accurate customizations, providing a comfortable and aesthetically pleasing fit for the patient. The prosthetics are also highly durable, providing a long-term solution for dental restoration. As this method continues to grow in popularity, it is likely to become the preferred method for creating custom dental prosthetics.

Crowns fabricated by titanium alloy

Dental titanium crowns are a popular choice for restoring teeth as they are strong and durable. They are used in both cosmetic and restorative dentistry and can be used to create custom crowns that are designed to fit any patient’s mouth. Titanium is a metal alloy that is lightweight and non-toxic, making it a safe option for dental implants.

Titanium crowns are used to replace large sections of missing or damaged tooth enamel. The crown is fitted over the remaining natural tooth structure and is held in place with a dental adhesive. Titanium crowns are made of thin layers of metal alloy, which are then heated and shaped to match the patient’s natural tooth shape. Titanium crowns provide a strong, durable and aesthetically pleasing solution to restoring teeth.

The process of fitting a titanium crown begins with the dentist taking an impression of the patient’s mouth. The impression processed with a professional 3d dental scanner is then used to construct a prosthetic crown in digital data.

3D scanning technology is becoming an increasingly popular tool in the field of dentistry. This technology is used to create custom dental prosthetics and restorations, allowing for a precise and aesthetically pleasing fit. 3D scanning technology offers a number of advantages over traditional methods, such as increased accuracy, reduced time and cost, and the ability to produce customized restorations.

One of the key advantages of 3D scanning technology is its accuracy. Traditional methods of creating dental prosthetics and restorations often require manual measurements and adjustments. This can lead to inaccuracies that can affect the fit and appearance of the prosthetic or restoration. With 3D scanning technology, the measurements are taken digitally and the prosthetic or restoration is designed according to the exact specifications of the patient’s mouth. This ensures a precise and aesthetically pleasing fit.

Another benefit of 3D scanning technology is the reduced time and cost associated with creating custom prosthetics and restorations. Traditional methods require multiple visits to the laboratory to take measurements and make adjustments. With 3D scanning technology, the measurements are taken digitally and the prosthetic or restoration can be created in a much shorter period of time. This reduces the cost of the procedure and allows for quick turnaround times.

3D scanning technology allows for the production of customized restorations. Traditional methods typically require a great deal of manual labor to create a prosthetic or restoration that matches the patient’s exact specifications. With 3D scanning technology, the prosthetic or restoration can be designed according to the patient’s exact needs, creating a perfect fit.

The combination of 3D dental scanners and CAD/CAM milling machines are revolutionizing the field of dentistry, allowing for the production of customized prosthetics with unparalleled accuracy and precision. With 3D dental scanners, dentists can quickly and accurately scan a patient’s mouth to create a 3D image of their teeth and gums. This image is then sent to a CAD/CAM milling machine, which can create a prosthetic to perfectly match the patient’s mouth.

The prosthetic is fabricated from a pre-selected block of material, such as cobalt chrome, titanium or zirconium. The CAD/CAM milling machine is programmed to cut the material into the exact shape needed to fit the patient’s mouth. The entire process is done in a single visit and requires no further follow-up appointments, drastically reducing the amount of time needed to create a customized prosthetic.

The combination of 3D dental scanners and CAD/CAM milling machines has revolutionized the field of prosthesis production, allowing for the production of customized prosthetics in a fraction of the time it used to take. This technology has allowed dentists to provide their patients with prosthetics that are comfortable, secure, and aesthetically pleasing, giving them a renewed sense of confidence in their smile.

Finally, the crown is then fitted over the existing tooth structure and is held in place with a dental adhesive. Titanium crowns come in a variety of sizes, shapes to match the patient’s specific needs.

Titanium crowns have a number of advantages over traditional dental crowns. Titanium crowns are resistant to wear and tear, which means they can last up to 15 years. They are also highly resistant to staining and discoloration, which helps to maintain a natural and aesthetically pleasing appearance over time. Titanium crowns are also less likely to cause adverse reactions in patients, as they are non-toxic and hypoallergenic.

Titanium crowns also offer a number of other benefits, such as being highly biocompatible and providing a secure fit. Titanium is strong and durable, making it a great choice for dental restorations. Titanium crowns can be used to restore teeth that have been damaged due to decay, trauma, or wear and tear.

In conclusion, titanium crowns are a great choice for restoring teeth and can provide a natural and aesthetically pleasing solution. They are strong and durable, and can last up to 15 years. They also come in a variety of sizes, shapes, and colors to match the patient’s specific needs. Titanium is a safe and non-toxic material, making it a great choice for dental restorations.

Titanium blocks CAD CAM products info

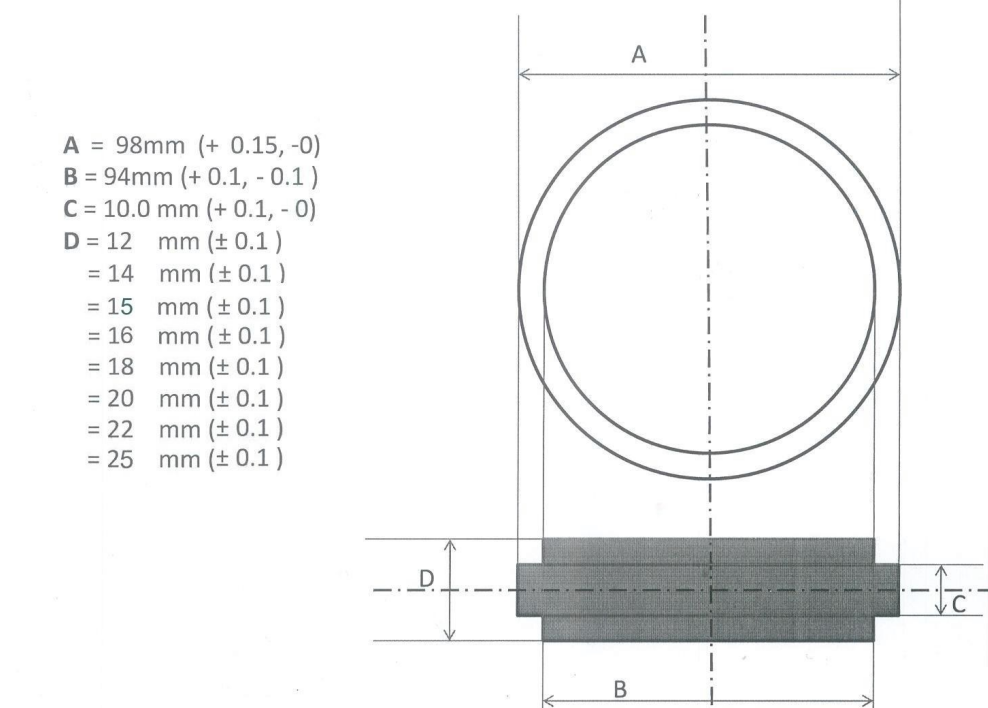

Titanium blocks apply for dentistry CAD/CAM application, products are in grade 5 standard. Open system, and zirkon zahn milling dental system are compatible. Blocks height size range from 10 to 30 mm available.

Specification

| Grade | GR5 |

| shape | Open system 98 mm and 95 mm with step Zirkonzahn dentistry CAD/CAM |

| Titanium content | ≥99.5 (%) |

| Impurity content | <0.02 (%) |

| Density | 4.51 |

| Standard | ASTM F67, ASTM F136/ISO 13458 |

| Size | 1. Diameter 98 mm, 95 mm 2. Height 10 mm, 12 mm, 14 mm, 16 mm, 18 mm, 20 mm, 25 mm,30 mm |

| Technique | Forged and CNC Machined |

| Application | Dental CAD CAM IMPLANT, Crowns, Bridges, Abutments etc. |

Chemical composition

| Grade | Al | V | N≤ | C≤ | H≤ | Fe≤ | O≤ | Other elements (single) | Other elements (sum) |

| Gr5 | 5.5~6.75 | 3.5~4.5 | 0.05 | 0.08 | 0.015 | 0.30 | 0.20 | 0.1 | 0.40 |

Mechanical performance data

| Grade | Tensile strength | Yield strength | Elongation | Section shrinkage |

| Gr5 | 895MPa | 825MPa | 10% | 20% |

Complete information about the CAD-CAM titanium blocks, click here.