Blog

Get To Know Extensive Types Of Surgical Handpiece In Dentistry

Electric handpiece system VS Air driven advantages in dentistry

Dental enamel and dentin must be removed and shaped in order to do restorative dentistry. In the past, hand instruments were also used for this, but their use was more restricted and difficult. Additionally, hand tools produced a lot of heat, which might be damaging to the tooth’s critical structures. The handpiece is among the most crucial elements of dental practice. It can be applied as a tool for efficiency and accuracy in everything from minor adjustments to everyday tasks. An electrically powered tool that rotates dental instruments operates effectively and precisely. Dental handpieces are the most often utilized piece of rotary equipment in dental offices. Dental handpieces have revolving motors and burs to trim and cut dental structures.

The power and precision dental professionals require from their handpieces are both delivered by electric dental handpiece systems. These devices frequently provide more and more consistent torque than air-driven handpieces since they rotate the bur using an electric motor rather than the office’s air supply. Electric handpieces are better able to maintain constant cutting speed and power for smoother cuts and margins because of this precision. These electric systems can be utilized with a variety of handpieces, including straight and contra-angled handpieces. Some electric systems also provide programs for endodontics and implant usage. Make sure to pick an electric handpiece system with the functionality you require, a cozy style, and a simple control layout.

Electric dental handpiece systems provide both the power and precision dental professionals expect from their handpieces. Using an electric motor rather than the practice’s air system to rotate the bur, these systems can often offer more and more consistent torque than air-driven handpieces. The fact that electric handpieces keep a constant pace while in operation is their first advantage. Additionally, the torque is constant. When using the machine on solid materials and cutting through dental crowns, helps to avoid unexpected stalls and speed changes.

A dentist’s handpiece or dental drill is a crucial tool. The majority of dental procedures employ it. In order to prepare a tooth for a dental repair such as a dental crown, bridge, or filling, the decayed and damaged section of the tooth must be removed using handpieces. The Fiber Optic Trans-illumination is a diagnostic device that emits a concentrated ray of bright light. The intense light may uncover cavities positioned in between teeth or beneath restorations. It is also able to discover cracks on your teeth that are not noticeable to the naked eye.

A handpiece that emits light to illuminate the oral cavity using a transparent fiber or cellular optic bundle. Handpieces have developed along with dental technology and dental practice. High-speed air-driven instruments can run at speeds up to 400,000 rpm, but they typically operate between 180,000 and 330,000 rpm. High-speed electric handpieces have a speed of 200,000 rpm. On contact, high-speed handpieces run at speeds between 180,000 and 350,000 rpm and have speeds of 400,000 or more rpm. The maximum rotating speed of the electric handpiece is 40,000 rpm (as opposed to 400,000 to 500,000 rpm for air-driven devices), but a complex gear arrangement allows it to be “pushed” to 200,000 rpm.

DENTAL SURGICAL HANDPIECE:

They can cut through just about anything, remove the dental structures to form margins, and prepare cavities for fillings or crowns. During surgery, they are also employed to section a tooth.

Electrical and air turbine powering solutions are available for handpieces. Compressed air is used to power an air-driven rotating turbine that produces rotation in air-driven handpieces. They have a variable torque and can spin up to 400,000 times per minute. Electric motor handpieces are self-contained systems since they employ an electric motor to move the head. They can run at continuous torque (consistent power) at up to 200,000 rpm because of internal gearing.

Enamel and tissue can be removed quickly with high-speed handpieces, sometimes known as “high speeds.” They can cut through just about anything, remove the dental structures to form margins, and prepare cavities for fillings or crowns. They are also employed during surgery to segment a tooth.

Slow-moving dental handpieces are used for prophy work, polishing, trimming, finishing cavity preparation, and removing soft decay. They run with an internal motor at a typical speed of up to 80,000 rpm and are referred to as “slow speeds.” They are utilized with attachments that serve a variety of purposes.

Here is a brief explanation of the most popular handpiece kinds and their current use.

- High-speed handpiece (air turbine).

- Low-speed handpiece for an air turbine.

- surgical handpiece

- endodontic handpiece

- Handpieces for implants.

- oral surgery handpiece

- surgical handpiece with a 45° angle

- surgical handpiece with a contra-angle

- surgical electric handpiece

- 4:1, 16:1 speed reduction endo handpiece

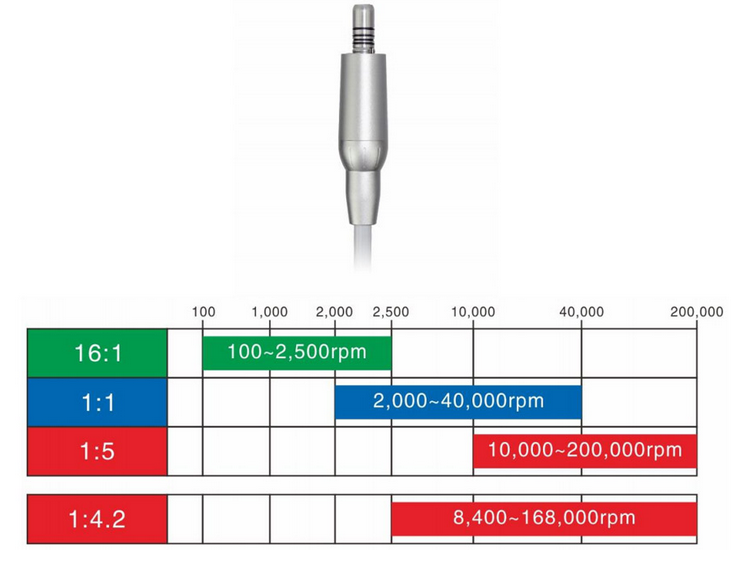

- 1:5, 1:4.2 increasing speed electric handpiece

- 20:1 speed reduction contra-angle handpiece

- SURGICAL HANDPIECE ORAL SURGERY

For oral and maxillofacial surgery as well as implantology, surgical straight handpieces have been specifically created. They are especially strong due to the high-quality stainless steel and unique treatment. Oral and maxillofacial surgery as well as implantology have been the focus of the creation of surgical straight handpieces. They are especially durable because of the premium stainless steel and unique treatment.

In a 3-predictor model, handpiece run time was unrelated to operator experience (P =.763) but increased with the number of teeth and surgical case complexity (both P .001) (both P .001). At least one second of the 20/50 rule was broken in 94 out of 100 cases, and 42% of total run seconds were broken. For safe oral surgery, an air-driven surgical handpiece is necessary. The grated vents on these surgical handpieces stop air from spraying into your oral cavity while you’re sedated. This is significant because problems could arise soon.

- IMPLANT HANDPIECE

The oral and maxillofacial surgeons were the ones who designed the implant handpieces. They are particularly robust since they are constructed from premium stainless steel with a specific coating.

The dental implant handpiece system has been actively employed for the insertion of single implants as well as for patients who are completely or partially edentulous up until recently. The most crucial aspect for placing dental implants has been shown to be its initial stability; a torque of 35 Ncm is advised. Particularly, it has been shown that initial stability is highly related to bone quality, placement torque, and implant type.

One of the equipments most frequently used in implant surgery is a 20:1 surgical handpiece.

When choosing a dental implant handpiece 20:1 device, especially for a busy dental practice, dependability and performance are crucial.

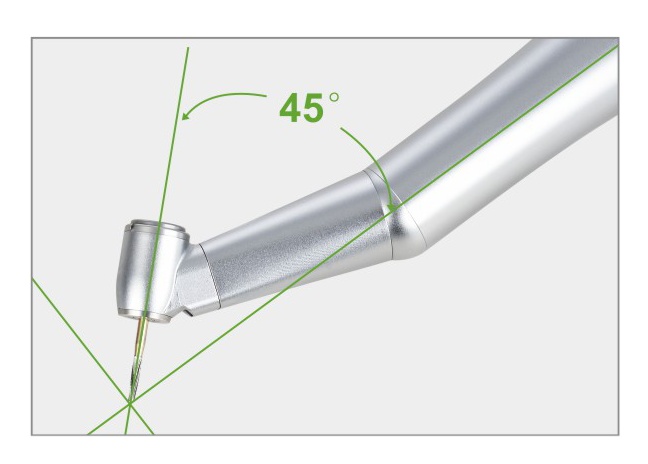

- 45-DEGREE SURGICAL HANDPIECE

The handpiece’s 45° angle has been specifically chosen for its many benefits. Surgery professionals, for whom this handpiece was primarily designed, will soon appreciate being able to perform effectively in small places. Particularly with wisdom tooth extractions, extensive spreading of the cheek’s soft tissues is not necessary. Work may be done swiftly and safely in the retromolar region thanks to the handpiece head’s design and a small spin of the head during preparation. Speaking of working rapidly, the instrument has a top speed of 100,000 rpm, and its tiny attachment head and expert cooling system take care of all issues connected to thermal effects and impede-free operation.

The drilling and polishing points on the contra-angle handpiece are spun by an electric motor. Several rotating instruments can be inserted into the contra-angle handpiece. The contra-angle handpiece can be taken out, cleaned, and sterilized after use.

An amazingly nontraumatic cut in the separation of tooth and root is made possible by the professional design of the bearings inside the handpiece head, which also ensures the silent operation of the bur.

The handpiece for the 45° contra-angle is really cozy to grasp. The working head matches the angle of your index finger fairly immediately, and as a result, the desired movement is simply translated along a few imagined centimeters parallel to the tip.

- CONTRA ANGLE SURGICAL HANDPIECE

The contra-angle handpiece is a dental instrument that uses a motor to spin the drilling and polishing points. The contra-angle handpiece is capable of accepting a variety of rotating instruments. The contra-angle handpiece can be taken out, cleaned, and sterilized after use.

In dentistry, a handpiece called a dental contra angle is employed to access the mouth’s most difficult-to-reach locations. The rotary instrument’s shaft has an angle thanks to one or more bends in the dental contra-angle.

The burs are perpendicular to the handpiece plane, and the head is inclined in a contra-angle handpiece. It is used in restorative dental operations like crown cutting and repair. A contra-angled handpiece offers stability and easy access in the dental operating technique.

Your teeth can be straightened without surgery. A contra-angled handpiece offers stability and easy access in the dental operating technique.

This study discusses a closed-system contra-angle dental handpiece with a tiny turbine propelled by a high-speed fluid stream. The American Dental Association and the National Bureau of Standards collaborated to produce this handpiece. Many of the arguments against the use of high rotating speeds in cavity preparation can be disproved by the use of this novel instrument because of properties inherent in hydraulic systems. A flexible coaxial double tubing is attached to the contra-angle handpiece. The 5/f> inch outer tube returns the used fluid to the reservoir while the Ys inch inner tube delivers the propellant fluid (water) under pressure to the contra-angle headpiece. The tube connects to the line going straight from the pump, the line going straight to the reservoir tank, and so forth. The operator may control the fluid flow to the headpiece Standards by using a relay system that is attached to a flexible rubber hose that lies on the floor.

- ELECTRIC SURGICAL HANDPIECE

They can cut through most materials, are used to remove tooth structure and form margins, and prepare cavities for restoration or crowns. During surgery, they are also employed to section a tooth. They seem like one-piece devices with a small curvature, and when operating, they are much noisier than slow-speed handpieces. The power and precision dental professionals require from their handpieces are both delivered by electric dental handpiece systems. These devices frequently provide more and more consistent torque than air-driven handpieces since they rotate the bur using an electric motor rather than the office’s air supply.

Electric handpieces at low speeds are a significant advancement over air-driven handpieces. On the other hand, high-speed electric hand-pieces provide the benefits touted for them, but at a great cost. The fact that electric handpieces keep a constant pace while in operation is their first advantage. Additionally, the torque is constant. When using the machine on solid materials and cutting through dental crowns, helps to avoid unexpected stalls and speed changes. Electric-driven handpieces offer continuous torque and speed when cutting in comparison to air-driven handpieces. The normal speed of air-driven handpieces is greater than 360,000 rpm. The variable cutting speeds and loss of power when force is applied are drawbacks of air-driven handpieces. Electric handpieces can rotate between 100 and 200,000 times per minute. (Yes, an electric bur can cut at 100 rpm.) Electric handpiece torque is in the 60-watt range (three times that of air-driven handpieces). Regardless of the material or speed range, the bur won’t slow down.

- 4:1, 16:1 SPEED REDUCTION ENDO HANDPIECE

Endodontic handpieces are specialist dental implements used during root canal treatments to clean and shape canals. In most circumstances, these tools can drive endodontic files with accuracy, preventing file breakage or binding. These handpieces work with your selected file system and other operatory equipment for precision, whether they’re reciprocating or rotating.

For dental needs in the field of dental surgery, a 20:1 contra-angle handpiece is used. Any other usage is dangerous and should not be done. The most typical contra angle is this one. The green band indicates a reduction handpiece, which runs at a lower rpm than the motor. as an example. Handpiece Speed at Ratio 4.1 is 5,000 RPM. Therefore, the 4:1 gear ratio is the most suggested alternative for M4 handpieces with endo motors. The safe rpm range for treatment with the 4:1 Handpiece is 500-3200 with the endo motor, which is constantly in this range.

- 1:5, 1:4.2 INCREASING SPEED ELECTRIC HANDPIECE

The speed-increasing handpiece is intended for a variety of applications. Standard models operate at a ratio of 1:5, so if your motor is running at 40,000 rpm, the handpiece’s speed can increase by 5 to 200,000 rpm.

High-speed dental handpieces operate at extraordinarily fast speeds between 180,000 and 350,000 revolutions per minute (rpm). Electric handpieces can rotate between 100 and 200,000 times per minute. (Yes, an electric bur can cut at 100 rpm.) Electric handpiece torque is in the 60-watt range (three times that of air-driven handpieces). Regardless of the material or speed range, the bur won’t slow down. High-speed air-driven machinery can operate at speeds of up to 400,000 rpm, but it typically runs between 180,000 and 330,000 rpm. However, their most significant drawback is that despite their rapid rate, the bur slows down when subjected to heavy loads because of their comparatively low torque.

A high-speed handpiece is a precision tool that removes tooth tissue swiftly and effectively with little pressure, heat, or vibration. Although it cuts the teeth swiftly, it must be handled carefully. Dental high-speed handpieces are available in a wide range of forms and materials, but they all rotate between 250,000 and 400,000 times per minute. High-speed dental tools can be distinguished by their attachment type, head size, light source (fiber optic lights), handpiece weight, and motor noise, among other features.

- 20:1 SPEED REDUCTION CONTRA-ANGLE HANDPIECE

A handheld motor known as a low-speed handpiece rotates the prophy cup and dental bur at 12,000 revolutions per minute (RPM). Usually, it is electric or air-driven. They are used to remove cavities and perfect cavity preparations during endodontic operations like root canal treatments. The low-speed handpiece’s angle design, construction material, air/water nozzles, and dental bur attachment vary depending on the manufacturer.

The handpiece may create much more torque thanks to speed-reducing gears. The typical speed of prophylactic hygienist handpieces and low speeds is 5,000 RPM. Attachments are used during endodontic and implant treatments to lower speed to 1,500 rpm or less and produce extremely high levels of torque for the best possible control.

-

Powder Jet Handpiece for Hygienists

Powder Jet Handpiece for Hygienists -

Obturation Pen for Root Canal Therapy

Obturation Pen for Root Canal Therapy -

3D Obturator Handpiece Filling System

3D Obturator Handpiece Filling System -

VersaCut – Advanced Saw Handpieces for Precision Dental Cutting

VersaCut – Advanced Saw Handpieces for Precision Dental Cutting -

Mini Head Handpiece For Child, Triple Spray

Mini Head Handpiece For Child, Triple Spray -

Intraoral Camera Handpiece

Intraoral Camera Handpiece -

Air Turbine Handpiece Anti Retraction

Air Turbine Handpiece Anti Retraction -

Contra-angled Handpiece Accessories | KaVo Compatibility

Contra-angled Handpiece Accessories | KaVo Compatibility -

Endodontic Activator

Endodontic Activator -

Handpiece Set

Handpiece Set -

Wrench Handpiece NSK Compatible

Wrench Handpiece NSK Compatible -

Speed 16:1 Endodontic Handpiece

Speed 16:1 Endodontic Handpiece -

Straight 1:1 Restorative Handpiece

Straight 1:1 Restorative Handpiece -

High Speed Hand-piece Air Driven Series,Fit NSK Fiber Optic Coupler

High Speed Hand-piece Air Driven Series,Fit NSK Fiber Optic Coupler -

Fiber Optic Hand piece-KaVo Multiflex Quick Coupling System

Fiber Optic Hand piece-KaVo Multiflex Quick Coupling System -

Endo Handpiece For Apex Locator

Endo Handpiece For Apex Locator -

45° Contra-angle Handpiece

45° Contra-angle Handpiece -

Surgical Straight Handpieces

Surgical Straight Handpieces -

Contra angle Endo Handpiece

Contra angle Endo Handpiece -

Red 1:5 Increasing Speed Handpiece

Red 1:5 Increasing Speed Handpiece -

4:1 Contra-angle Hand piece

4:1 Contra-angle Hand piece -

Air Abrasion Handpiece

Air Abrasion Handpiece -

Slow Speed Handpiece

Slow Speed Handpiece -

20:1 Reduction Contra Angle Handpiece

20:1 Reduction Contra Angle Handpiece -

Surgical Handpiece Dental Implant

Surgical Handpiece Dental Implant -

LED Light Dental Handpiece High Speed

LED Light Dental Handpiece High Speed -

Dental Handpiece Cartridge

Dental Handpiece Cartridge