Blog

Steps in sterilization of dental handpieces

As one of the most commonly used dental appliances, how to properly clean, disinfect and sterilize the dental handpiece plays an important role in the safety of the majority of patients.

Let’s take a closer look at the standard operating process of how to sterilize dental handpieces?

Prepare materials:

1. Cleaners and Disinfectants: Multi-enzyme solution

2. Various cleaning tools: soft brush, sponge, high-pressure water (air) gun

3. Protective equipment: protective clothing, goggles, or face shields

Chairside pre-cleaning:

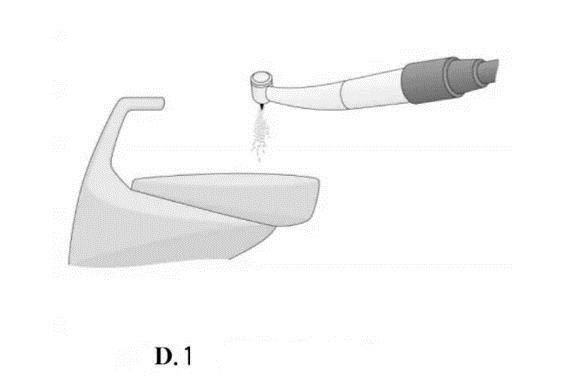

After using the dental handpiece with a bur, step on the foot brake in time to flush the handpiece lumen for the 30s, as shown in Figure D.1

Reduce back suction pollution, wipe with dressing, remove sticky dirt and dental materials on the surface of the dental handpiece in time

Manual cleaning:

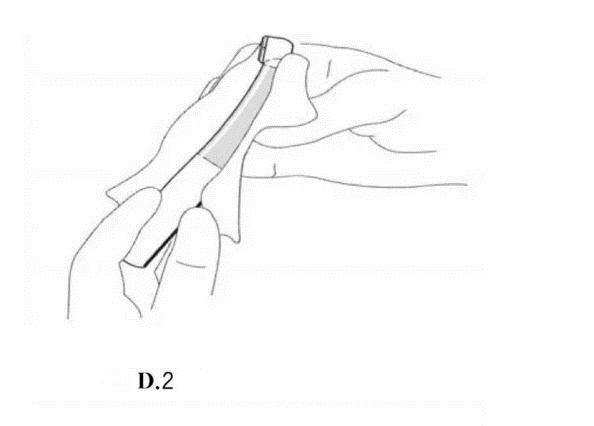

- Remove the dental handpiece from the quick connector or cable, remove the bur, and remove the surface contamination, as shown in Figure D.2

2. For dental handpieces with optical fiber, the particles, and dust on the surface of the optical fiber can be blown off with an air gun, and the stains on the surface of the optical fiber can be cleaned.

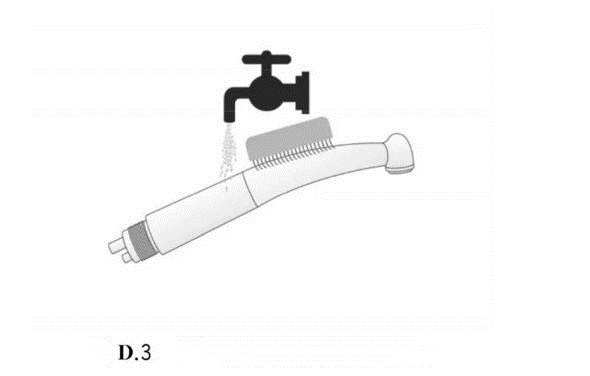

3. The surface of the threaded dental handpiece can be cleaned with a soft brush under running water, as shown in Figure D.3

4. Use a pressure can of cleaning lubricant to clean the handpiece air inlet line, or use a pressure water gun to flush the air inlet inner line, then use a pressure gun to dry

Notes are as follows:

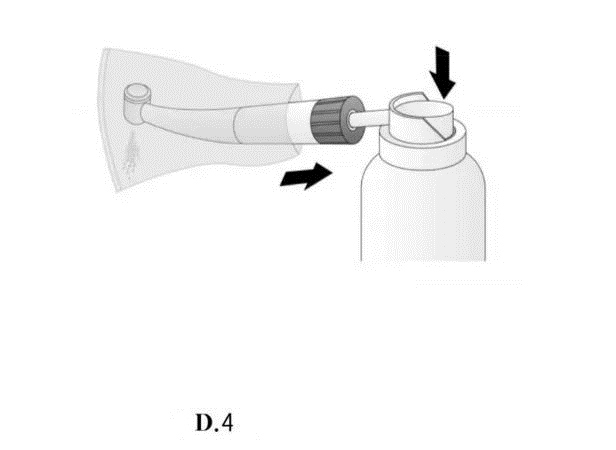

a. Use a transparent plastic bag or paper towel to wrap the handpiece head in the process of cleaning the lubricating oil in a pressure can to avoid the spread of oil mist, as shown in Figure D.4

b. The special handpiece for dental implants with detachable parts should be disassembled for cleaning; the special handpiece for implantation that cannot be detached can be cleaned with a pressure water gun for internal pipeline cleaning

c. After using the pressure water gun to clean the dental handpiece, use the pressure air gun to dry the internal air path as soon as possible to avoid bearing damage

d. The pressure of the pressure water gun and pressure air gun should be 200kpa~250kpa, and should not exceed the pressure marked in the manual of the dental handpiece

e. Handpieces should not be immersed in liquid solutions for cleaning

f. During the process of cleaning the interior with the canned cleaning oil, if there is dirt flowing out of the machine head, repeat the above operation 4 until no dirty oil flows out

final rinse:

1. Thoroughly rinse surface dirt and cleaning agent under running water: Thoroughly rinse surface dirt, debris, cleaning agent

2. High-pressure water gun for inner cavity cleaning: under the liquid surface, rinse through the driving hole of the handpiece, the time is 30s~60s

3. Soft or purified water final rinse

Mechanical cleaning:

1. After using the dental handpiece, use the water and air system of the dental integrated therapy table to flush the internal water channel of the dental handpiece with a bur for 30 seconds.

2. Put the dental handpiece into the mechanical cleaning equipment, fix the dental handpiece, and select the correct cleaning procedure

3. The mechanical cleaning equipment should be equipped with a special interface for the dental handpiece, and its cleaning water flow and airflow conform to the internal structure of the dental handpiece

4. Deionized water, soft water, or distilled water should be used for mechanical cleaning equipment

Notes are as follows:

a) Power motors should not be cleaned with a mechanical washer

b) Internal piping should be fully dried after handpiece cleaning

c) The dental handpiece should not be cleaned with ultrasonic first

d) The dental handpiece should not be cleaned at the same time as other oral instruments

dry:

1. Put it in a drying device for drying, or after cleaning, the surface can be dried with a low-fiber wiping cloth, and the inner cavity pipe can be dried with an air gun

2. Put it in the drying cabinet to dry, the temperature is 70℃~90℃, and the time is 5min~10min

Inspection and Maintenance:

manual maintenance

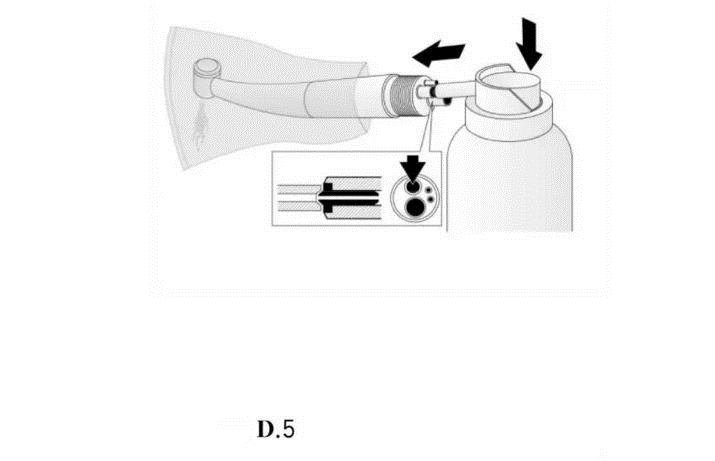

- Fill the handpiece with lubricating oil using the pressure-packed lubricating oil connection with the matching lubricating adapter or fitting, as shown in Figure D.5

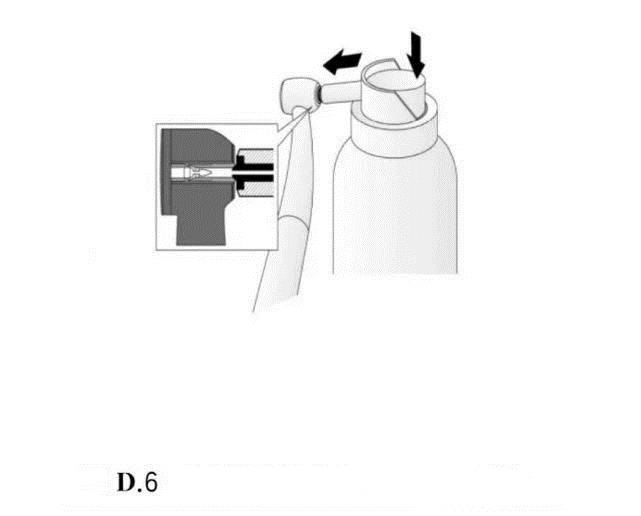

2. The part (chuck or three-valve spring) of the handpiece to support the instrument should be filled with oil every day, as shown in Figure D.6

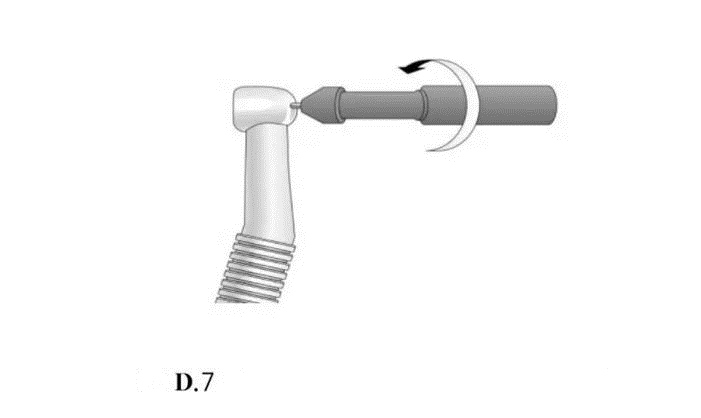

3. Grease pen should be used to lubricate the chuck or the three-valve spring and bearing for the internal oil circuit type dental handpiece, Figure D.7

4. Oil filling of low-speed contra angel dental handpiece and straight handpiece can refer to the above oil filling methods (if applicable). For special oil filling methods, refer to the manufacturer’s or supplier’s instruction manual.

Precautions:

a. When cleaning and filling oil, the oil filling joint should be fixed with the oil filling part of the dental handpiece to ensure the oil filling effect.

b. Select pressure-packed cleaning oil to clean the handpiece without refilling the oil

Mechanical maintenance:

1. Connect the dental handpiece to the matching oiling adapter or connector and insert it into the automatic oiling and maintenance machine for oiling

2. Select the appropriate oil injection program

Pack:

The paper-plastic bag should be sealed completely, and the sealing width should be greater than or equal to 6MM

The instruments in the bag should be more than or equal to 2.5cm from the seal of the packaging bag, and the paper bag should be sealed completely.

Sterilize:

Pressure dental autoclave machine should be preferred for oral devices

device storage:

Disposable crepe paper and medical non-woven packaging can be stored for 180 days, without packaging sterilization, storage can not exceed 4 hours.

Most popular dental handpiece products recommanded by Dental Lab Shop.

-

Powder Jet Handpiece for Hygienists$152.00 – $172.00

Powder Jet Handpiece for Hygienists$152.00 – $172.00 -

Product on sale

Obturation Pen for Root Canal TherapyOriginal price was: $1,400.00.$1,120.00Current price is: $1,120.00.

Obturation Pen for Root Canal TherapyOriginal price was: $1,400.00.$1,120.00Current price is: $1,120.00. -

Product on sale

3D Obturator Handpiece Filling SystemOriginal price was: $1,600.00.$1,080.00Current price is: $1,080.00.

3D Obturator Handpiece Filling SystemOriginal price was: $1,600.00.$1,080.00Current price is: $1,080.00. -

VersaCut – Advanced Saw Handpieces for Precision Dental Cutting$369.00

VersaCut – Advanced Saw Handpieces for Precision Dental Cutting$369.00 -

Mini Head Handpiece For Child, Triple Spray$55.00 – $79.00

Mini Head Handpiece For Child, Triple Spray$55.00 – $79.00 -

Product on sale

Intraoral Camera HandpieceOriginal price was: $600.00.$405.00Current price is: $405.00.

Intraoral Camera HandpieceOriginal price was: $600.00.$405.00Current price is: $405.00. -

Air Turbine Handpiece Anti Retraction$70.00 – $90.00

Air Turbine Handpiece Anti Retraction$70.00 – $90.00 -

Contra-angled Handpiece Accessories | KaVo Compatibility$45.00 – $214.00

Contra-angled Handpiece Accessories | KaVo Compatibility$45.00 – $214.00 -

Product on sale

Endodontic ActivatorOriginal price was: $239.00.$169.00Current price is: $169.00.

Endodontic ActivatorOriginal price was: $239.00.$169.00Current price is: $169.00. -

Handpiece Set$129.00 – $448.00

Handpiece Set$129.00 – $448.00 -

Wrench Handpiece NSK Compatible$49.90

Wrench Handpiece NSK Compatible$49.90 -

Speed 16:1 Endodontic Handpiece$59.00 – $282.00

Speed 16:1 Endodontic Handpiece$59.00 – $282.00 -

Straight 1:1 Restorative Handpiece$148.00 – $469.00

Straight 1:1 Restorative Handpiece$148.00 – $469.00 -

High Speed Hand-piece Air Driven Series,Fit NSK Fiber Optic Coupler$58.00 – $128.00

High Speed Hand-piece Air Driven Series,Fit NSK Fiber Optic Coupler$58.00 – $128.00 -

Fiber Optic Hand piece-KaVo Multiflex Quick Coupling System$63.99 – $235.00

Fiber Optic Hand piece-KaVo Multiflex Quick Coupling System$63.99 – $235.00 -

Endo Handpiece For Apex Locator$58.99 – $81.00

Endo Handpiece For Apex Locator$58.99 – $81.00 -

Product on sale

45° Contra-angle HandpieceOriginal price was: $799.00.$529.00Current price is: $529.00.

45° Contra-angle HandpieceOriginal price was: $799.00.$529.00Current price is: $529.00. -

Surgical Straight Handpieces$92.00

Surgical Straight Handpieces$92.00 -

Product on sale

Contra angle Endo HandpieceOriginal price was: $288.00.$149.00Current price is: $149.00.

Contra angle Endo HandpieceOriginal price was: $288.00.$149.00Current price is: $149.00. -

Red 1:5 Increasing Speed Handpiece$348.00 – $448.00

Red 1:5 Increasing Speed Handpiece$348.00 – $448.00 -

4:1 Contra-angle Hand piece$59.00 – $219.00

4:1 Contra-angle Hand piece$59.00 – $219.00 -

Air Abrasion Handpiece$228.90 – $282.00

Air Abrasion Handpiece$228.90 – $282.00 -

Slow Speed Handpiece$35.00 – $88.00

Slow Speed Handpiece$35.00 – $88.00 -

20:1 Reduction Contra Angle Handpiece$205.00 – $285.00

20:1 Reduction Contra Angle Handpiece$205.00 – $285.00 -

Surgical Handpiece Dental Implant$59.00 – $285.00

Surgical Handpiece Dental Implant$59.00 – $285.00 -

Product on sale

LED Light Dental Handpiece High SpeedOriginal price was: $100.00.$84.00Current price is: $84.00.

LED Light Dental Handpiece High SpeedOriginal price was: $100.00.$84.00Current price is: $84.00. -

Dental Handpiece Cartridge$15.99 – $78.00

Dental Handpiece Cartridge$15.99 – $78.00